Powder metallurgy goes beyond the manufacturing facility. Many of the products we manufacture have applications in everyday life. Whether it’s a part for the automotive industry, the lawn and garden industry or a small piece of medical technology, each part needs to be designed specifically for its intended use. The case study manufacturing articles are just a few examples that highlight some of our real life success stories. We approach each project with our focus on the end goal. It isn’t enough to produce powder metal parts. Our goal is to manufacture powder metal parts that meet or exceed the task they were designed for. Meeting that goal means choosing the right materials and designing around component guidelines. It means rigorous testing to ensure the product we produce exceeds performance expectations. It’s a process that starts with design and ends when we are mass producing the part. Catalus’ success stories come from the combined effort of our customers, our manufacturing team , our advanced engineers and our state-of-the-art equipment. Our work has been recognized for its design excellence in multiple industries, and we’re always working to improve our processes to produce better products. We accomplish that through active involvement in industry research and development. In fact, Catalus is currently the only company in the industry that has a research and development facility specifically dedicated to the powder metallurgy. Insights gained through research will be complemented by our state-of-the-art production facility, where we will be able to put new ideas into full-fledged production. With two facilities working together, we’re able to create world-class products that exceed expectations. In short, we’re proud of our work. Each case study on manufacturing that we’ve listed here represents a unique project, each with its own challenges and solutions.

Access Cover for Crankcase Ventilation System

Problem The part showed a propensity for cracking when [...]

Trip to Customer’s Production Line Pays Off

Client Over-the-road truck manufacturer Problem Customer was using a [...]

Feel

Client Marine Industry Problem Customer needed a "smooth feeling" [...]

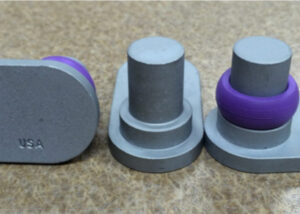

Rough in Tools

Client Recreational Vehicle Industry Problem Customer needed a flexible [...]