Catalus is an active member of MPIF—the Metal Powders Industry Federation (mpif.org). Catalus has representatives on the Standards Committee, the IDB (Industry Development Board), Powder Metallurgy Parts Association (PMPA) and the Center for Powder Metallurgy Technology (CPMT).

Catalus is an active member of MPIF—the Metal Powders Industry Federation (mpif.org). Catalus has representatives on the Standards Committee, the IDB (Industry Development Board), Powder Metallurgy Parts Association (PMPA) and the Center for Powder Metallurgy Technology (CPMT).

The MPIF, through their standards committees, establish and publish material standards and test methods that are used throughout the PM industry. MPIF standard 35 provides the chemical and physical properties for materials used throughout the industry. The Standard Test Methods for Metal Powders and Powder Metallurgy Products provides the details of how specific tests are conducted throughout the industry.

Catalus has invested heavily in our materials laboratory so that we, on site, can conduct detailed metallurgical and physical property tests on powders we purchase, parts we make, and parts produced by our competitors.

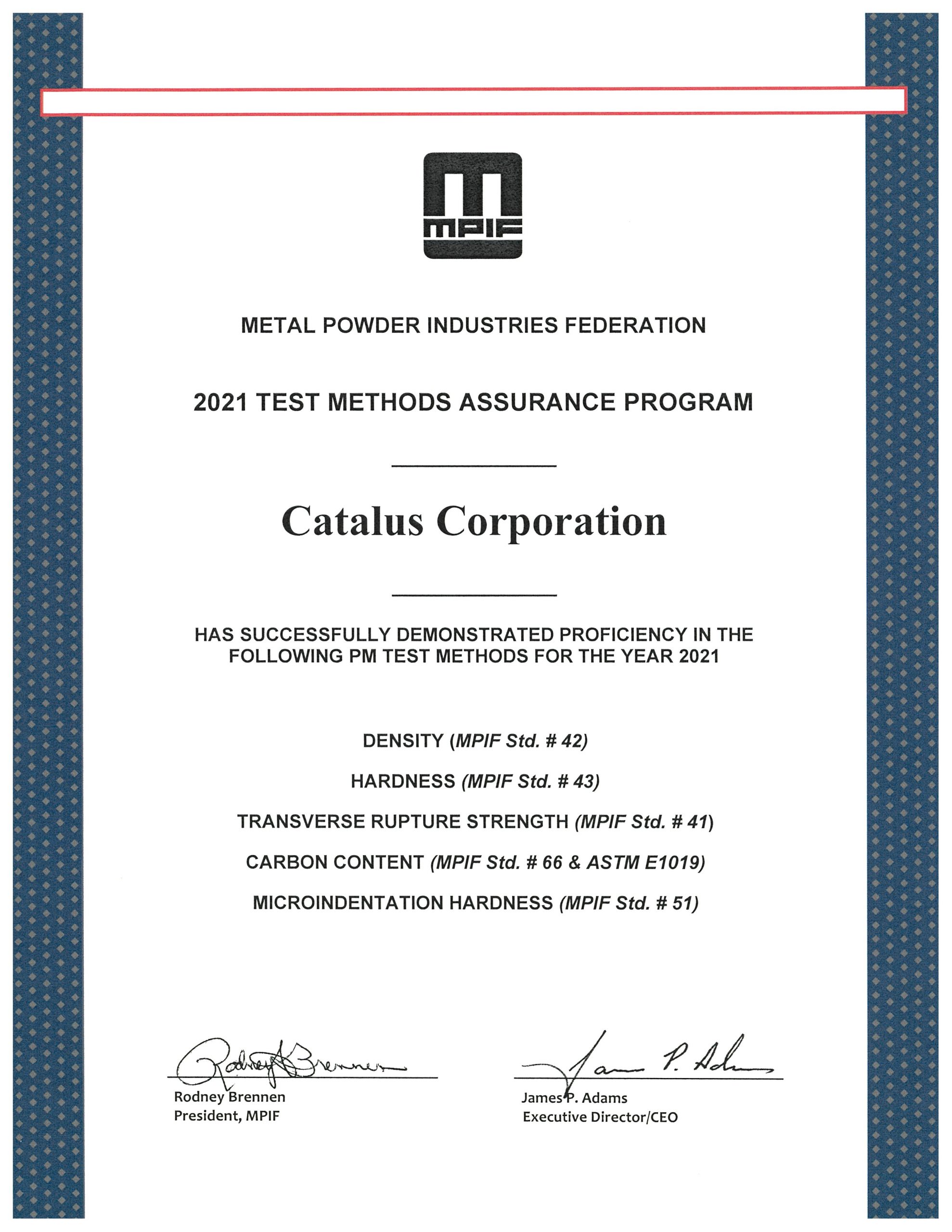

In order to verify that we are conducting tests properly and that our results are accurate, Catalus also participates in the MPIF Test Methods Assurance Program. Under the direction of the MPIF Standards Committee activity, TMAP is conducted by Dr. Leander F. Pease III, FAPMI, PMTII of Powder-Tech Associates. It is a unique industry service for MPIF members that work with conventional PM materials/products. The program started in 1994, and Catalus Corporation has participated in this program every year since 2000.

The objective of the TMAP program is to demonstrate that a group of companies can follow the test method standard procedures and get consistent, reliable data. These procedures used are listed in the latest Standard Test Methods for Metal Powders and Powder Metallurgy Products. There are five (5) program tests we participate in: Density #42, Apparent Hardness #43 and TRS (Transverse Rupture Strength #41.) We also participate in Microindentation Hardness Testing #51, and Carbon Content Testing #66.

The testing is completed when the MPIF sends sample materials to Catalus and we are required to do our analysis and report the results back to TMAP. Our results are evaluated by TMAP and we receive a report from TMAP regarding our accuracy.

Because of the equipment and time investment required, not all powdered metal parts manufacturers choose to or can afford to participate in this program. Catalus believes that accurate metallurgical properties are key to our being able to provide quality parts to our customers, to assist in part analysis, and to our developing new products for the future.

Applicable links