Based on the latest estimate, there is an average of 65 pounds of powder metallurgy automotive parts in each vehicle manufactured. Since the 2008-2009 recession, the consumption of iron-based powders has been on a steady upward trend. To put that in perspective, the amount of iron powder today is 2.375 times greater than in 2008-2009.

Advantages of Powder Metallurgy Auto Parts

The growth of powder metal components in automobiles can be directly attributed to innovations in the material development and pressing technology. Through research and development, materials available today can be pressed to higher densities resulting in higher strength materials. A few of the powder metallurgy advantages for auto parts production include:

- Ability to produce materials at a higher density and strength

- Capable of producing increasingly complex parts

- Cost-effective manufacturing of auto components

Pressing technology has evolved so much that parts manufacturers like Catalus can produce more complex parts. These auto parts can be produced with up to seven or eight different levels while maintaining equal density on each level. The ability to press such complex powder metallurgy parts results in less machining costs. Even when machining is required, materials have been developed that have machining additives right in the mix. This can possibly eliminate the need for resin impregnation.

Application of Powder Metallurgy Parts in Automobiles

Year after year, powder metallurgy is used for new and different parts in cars, trucks, and SUVs. However, Catalus has found that many engineers and designers still don’t have a full understanding of how versatile and robust this process has become. Through design assistance and PM 101, Catalus continues to expose what all can be done with this advanced manufacturing process.

Iron-based powders and stainless steel powders make up the bulk of what is consumed. Applications in the automotive industry include but are not limited to:

- Steering components

- Transmission components

- Connecting rods

- Main bearing caps

- Variable valve timing (VVT sprockets)

- Seating applications

- Exhaust applications

- Catalytic reduction system

- Fuel system components

- Engine components

Each powder metallurgy component made has a name that appears on the blueprint. Each of these powder metal parts is produced with a specific set of tools and parameters that are unique to that part. Some of the names of these powder metallurgy products include:

- Pulleys

- Thrust and backup washers

- Differential gear sets

- Helical gears

- Bevel gears

- Planetary gears

- Sprockets

- Output pulleys

- Fuel system flanges

- Exhaust flanges

- Access covers

- Spacers

- Racks

- Triggers

- Torque limiters

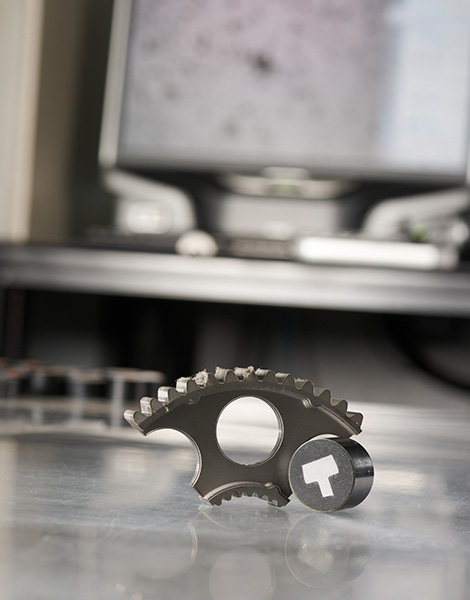

- Cams

- Pawls

- Pump components

- Sector gears

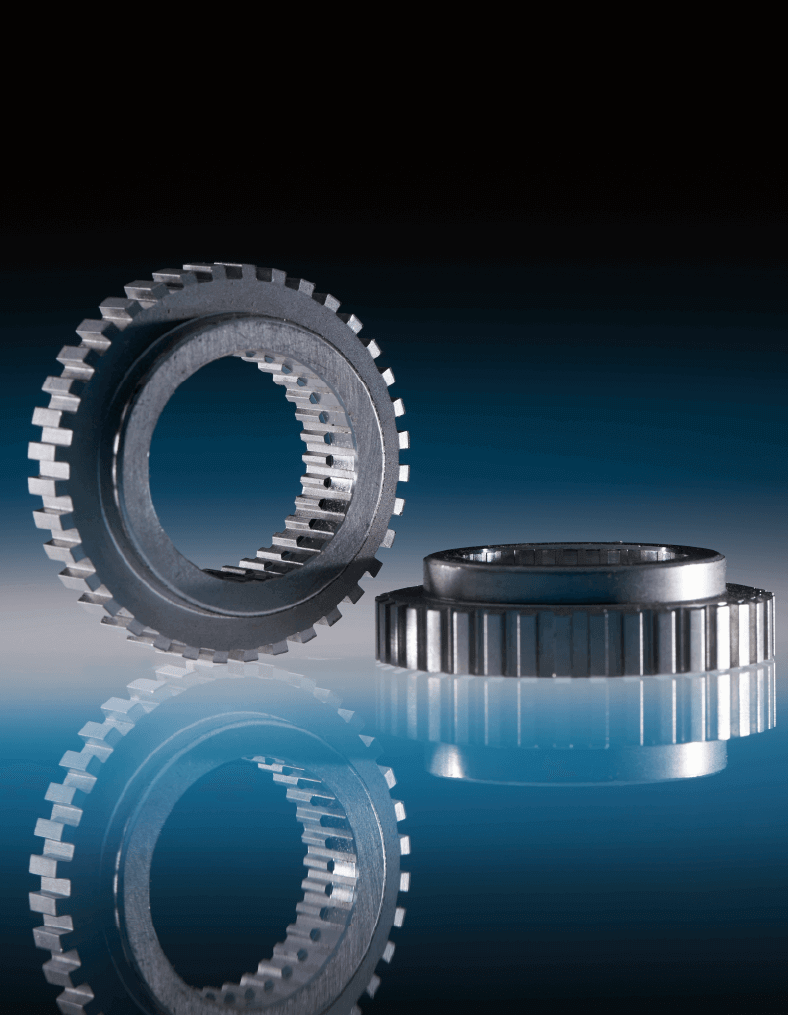

- Tone rings

- Timing gears

- Backing plates

- Shock absorbers

Much of the development in automotive powder metallurgy production has come through conversions and reverse engineering. Often in the powder metallurgy process, two or more non-PM components can be combined. This results in cost savings and a reduced parts list.

Powder Metallurgy Parts in Automobiles FAQs

Catalus is a Leading Manufacturer of Powder Metallurgy Auto Parts

Catalus has been, is, and will continue to be a significant player in the automotive market. Catalus is certified to the IATF-16949 standard; the quality management system required by automakers. The powder metallurgical engineering systems we have in place are stringent, meaning we dot our I’s and cross our T’s on a daily basis.

Catalus is willing to try newer and more difficult components. We are large enough to be a significant player and small enough to remain agile…something required for today’s automotive market.

Catalus is continuing the expand the use of our R & D center in our Galeton location. Our new manufacturing facility in St. Marys was designed with powder metal product flow in mind. Catalus has been awarded a number of perfect quality awards by our automotive customers and we have received Design Excellence Awards for two of our products supplied to the automotive industry.